IVORY COAST

Abidjan

Italy’s largest private equity

company in the Ivory Coast

Production

We process the fish directly where it is caught.

Production phases

Entry into the factory

Upon receipt at the plant, before being accepted as a raw material for our production, the tuna undergoes a series of strict quality controls to certify its organoleptic properties. All these processes are carried out without interrupting the cold chain.

Unloading the tuna

The tuna is unloaded from the fishing boat holds in the port of Abidjan and transported to the nearby plant with no further handling.

Cutting

During this phase, the tuna is “sorted” by its size to ensure that it can then be evenly cooked, which helps enhance all the qualities of the processed raw material.

Cooking

The subsequent tuna defrosting process happens slowly and gradually, before it then moves on to the cooking phase, in water or by steam, using simple, natural methods.

Cleaning the fish

After cooking, there is a cooling and firming phase of the fish meat, and only after this phase is the cleaning phase carried out, a process which is exclusively done by hand to preserve the highest quality for our products.

Canning

The time has now come to can the tuna: only the best fillets are selected, focusing on the quality of our preserved fish.

Sterilisation

The closed cans are sterilised at a temperature of -120°C, which helps remove any potentially harmful micro-organisms and keeps the product stable for a long period of time.

Packaging

Once ready, the cans are put on pallets to be shipped to European markets.

Quality controls

Our preserved fish undergoes strict quality controls starting from receipt of the raw material and all throughout production, guaranteeing the highest quality for the end product.

150,000,000

cans of tuna, jars and bags produced every year

23,000

tonnes of processed tuna a year

26,000 sq m

owned production plant in the Ivory Coast

10,000

tonnes of refrigeration capacity

Airone Ivory Coast

Our Abidjan team

Dante Bigi

Chairman

Chairman

Sergio Tommasini

CEO

CEO

Pietro Serra

Factory manager

Factory manager

Vanessa Gnanda Die

CEO Assistant

CEO Assistant

Nina N’dri

HRD / Legal and external relations

HRD / Legal and external relations

Aminata Bakayoko

Purchasing service manager

Purchasing service manager

Sika Mambo

DGM - FM

DGM – FM

Gouede Arsene Bieu

Quality systems manager

Quality systems manager

N’da Kouakou Germain Gbambau

Warehouse 2 manager

Warehouse 2 manager

Nogbou Jeannot Ekpo

Process control manager

Process control manager

Rodolphe Olou

Technical manager

Technical manager

Bodje Roland Kouassy

Laboratory manager

Laboratory manager

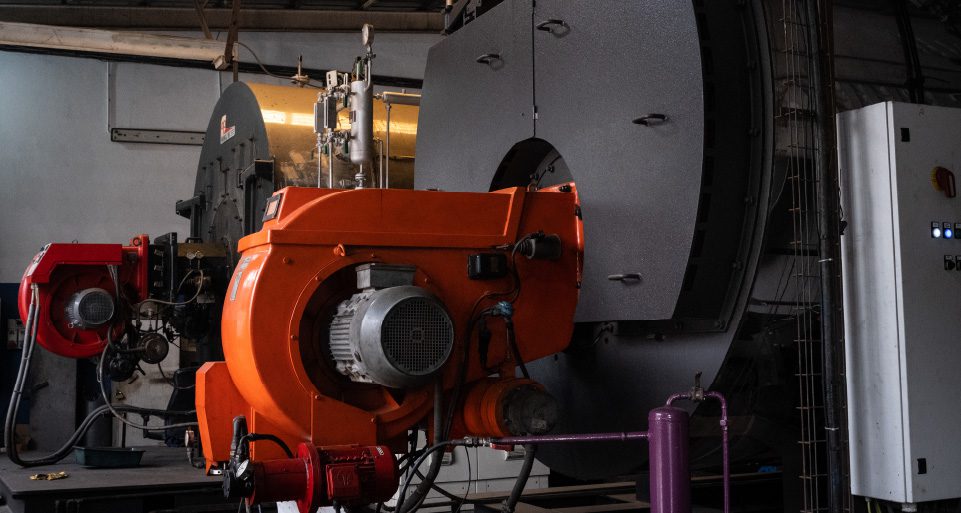

Italian Innovation

We call ourselves flag-bearers of ‘Italian nation branding’ and we really do this thanks to our long-standing collaboration with leading Italian companies on the market, which have helped us innovate and upgrade our production process. From our production machinery to our lorries for transporting the fish, they are all “made in Italy”.

Analysis laboratory

Our laboratory

We check every production lot every day to guarantee the highest quality for our products.

Certifications